BASIC INFO

HYSW-200W Automatic Linear Cuff Type

PE Film Wrapping Shrinkage Packing Machine

Product Introduction

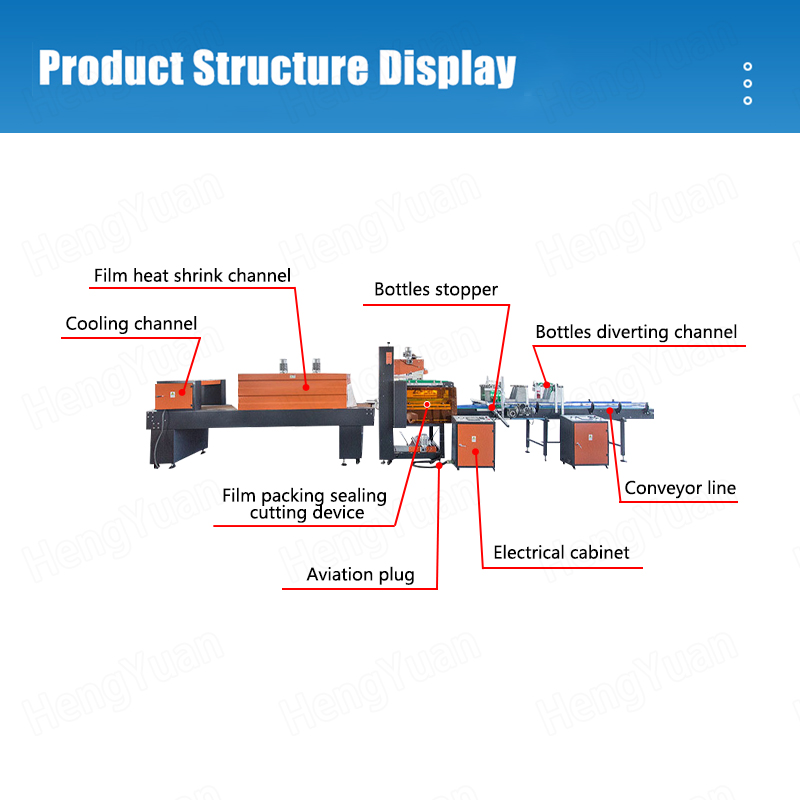

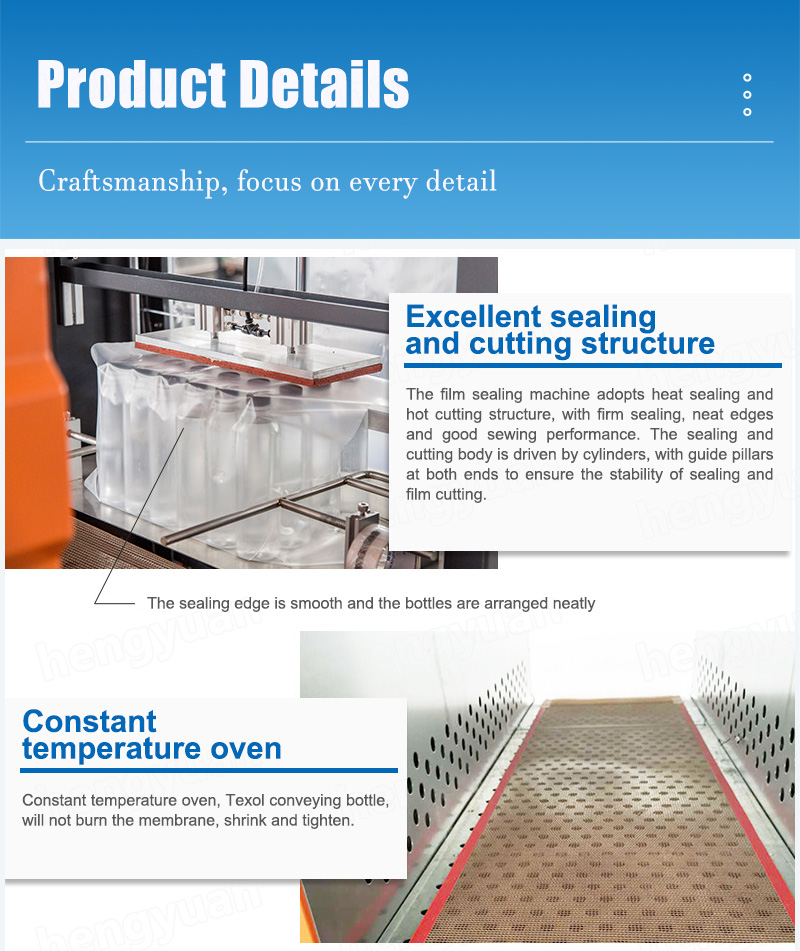

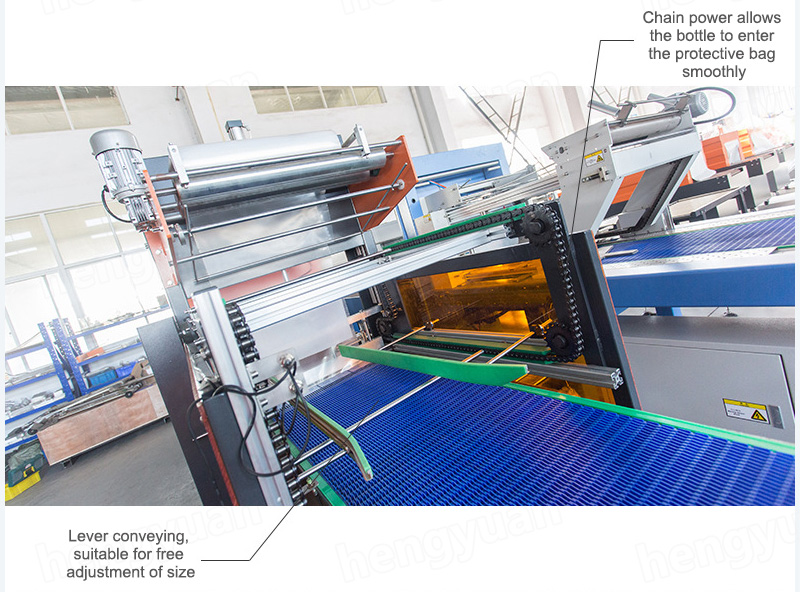

The cuff-type shrink wrapping machine is a state-of-the-art packaging solution designed and engineered for efficiency and continuous operation, leveraging the unique properties of heat-shrinkable film. This machine expertly arranges individual PET beverage bottles or similar items into groups, automatically assembles them, and then envelops them in shrink film. Through the processes of heating, contraction, cooling, and shaping, it creates a cohesive, tightly bundled package with a regular, aesthetic appearance that is also user-friendly to open. As such, this versatile equipment finds extensive application in industries such as food, pharmaceuticals, chemicals, and various light industrial product sectors.

Product Application

Cuff type PE Film Wrapping Shrinkage Packing Machine, Water bottles film shrinkage packaging machine, juice bottles carbonated drinking bottles, tea drinking bottles packaging equipment, coffee drinking bottles PE film packer, energetic drinks bottles shrinkage packer, soda bottles PE film shrinkage packing equipment, lubricant oil bottles PE film packaging machine, etc.

HYSW-200W Automatic Linear Cuff Type PE Film Wrapping Shrinkage Packing Machine

| Technical Parameters |

| Feeding Horizontal Dimension | 900±50mm |

| Wrapping Film | PE |

| Film roll width | ≤580mm |

| Film thickness | 0.06-0.12mm |

| Diameter of film roll | ≤400mm |

| Suitable for | PET Bottles, Plastic bottles, Glass bottles, Cans, etc. |

| Wrapper Outer Diameter | ≤300mm |

| Max Packing Size | L480*W300*H350mm |

| Sealing and cutting temperature | 180℃-220℃ |

| Shrinking temperature | 200℃-220℃ |

| Electric | AC 3Phases |

| Power | 29KW |

| Air Pressure | 0.5-0.7Mpa |

| Air consumption | 100NL/min |

| Working noise | ≤65DB |

| Capacity | 12-15bags/min |

| Shrinking Speed | 0-10m/min |

| Shrikage Chamber | 240x100x50cm |

| Overall Dimension | L9600*W140*H210 Cm |

| Weight | 2500Kg |

| Material | Carbon steel |

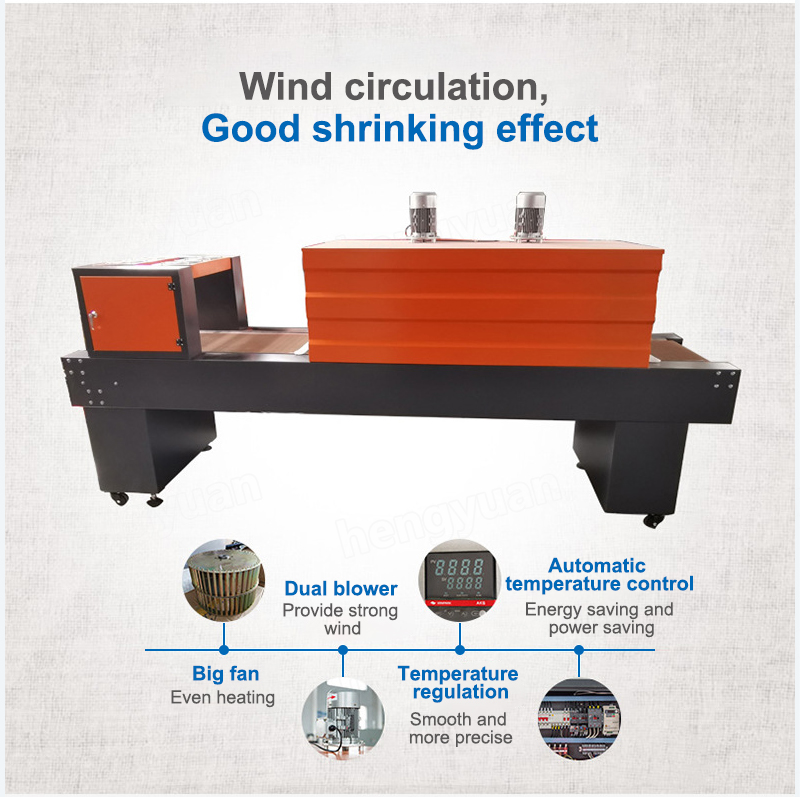

Main Features

1. Automatic control of shrinking and sealing temperatures, adjustable according to specific needs.

2. Constant temperature sealing blade coated with Teflon, ensuring smooth and secure cuts.

3. Controlled by a Programmable Logic Controller (PLC).

4. Touchscreen operation with a user-friendly interface for seamless human-machine interaction and control.

5. Capable of bottomless packaging, suitable for varying bottle diameters and combinations.

6. Easy to operate and maintain.

English

English Chinese

Chinese