1.The computer quantitative filling machine consists of feeding system, weighing system, frame, pneumatic control system, control system and powerless raceway.

2.Feeding mode: Require continuous and stable feeding (using feeding pump or hopper pressurized feeding)

3.The feeding mechanism is operated by solenoid valves through the cylinder for fast and slow feeding.

4.Filling method: conventional filling and lifting submerged filling (when ordering according to need)

5.The weighing system consists of weighing bracket, sensor and weighing platform with powerless drum and frame support and filling system.

6.Pneumatic control system: control fast and slow feeding valve.

7.The weighing platform is not allowed to be subjected to additional external forces during use.

1.The system uses weighing filling, with high measurement accuracy and is not affected by materials.

2. The feeding valve composed of fast and slow feeding can not only improve filling speed but also improve filling accuracy.

3. The measurement range is wide and the measurement error is less than 10 g/barrel.

4. The filling head adopts anti-drip and leak device, and the filling material has no bubbles, so the effect is good.

Main Technical Data

- Filling nozzles number: 2, 1, 4 pcs

- Filling capacity: around 250-300 barrels/hour (5 liters, 2filling nozzles)

- Applicable bottle height: unlimited

- Filling capacity: 1-5Kg

- Filling accuracy: <0.5%

- Available Bottle Diameter: No Limitation

- Power supply: 1.5KW

- Weight: 180Kg

- Size: 800X800X1500mm (length * width * height)

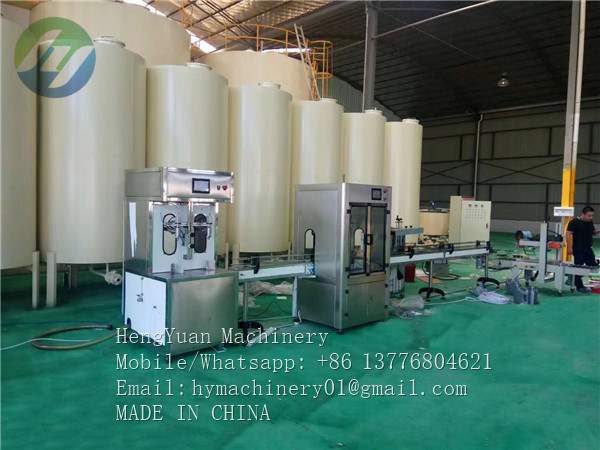

Semi Automatic 0.5-5kg Weighing Type Bottle filling machine Pictures

Semi Automatic Weighing Bottle filling machine is suitable for below bottle samples

Click here to view Automatic Inline Drum filling machine running video on YouTube

https://youtu.be/BLBAc37oGos

Contact us to get more information and quotation

-

Email : sales@myhymachinery.com

-

Skype: hymachinery01@hotmail.com

-

Mobile/Whatsapp: +8613776804621

English

English Chinese

Chinese