BASIC INFO

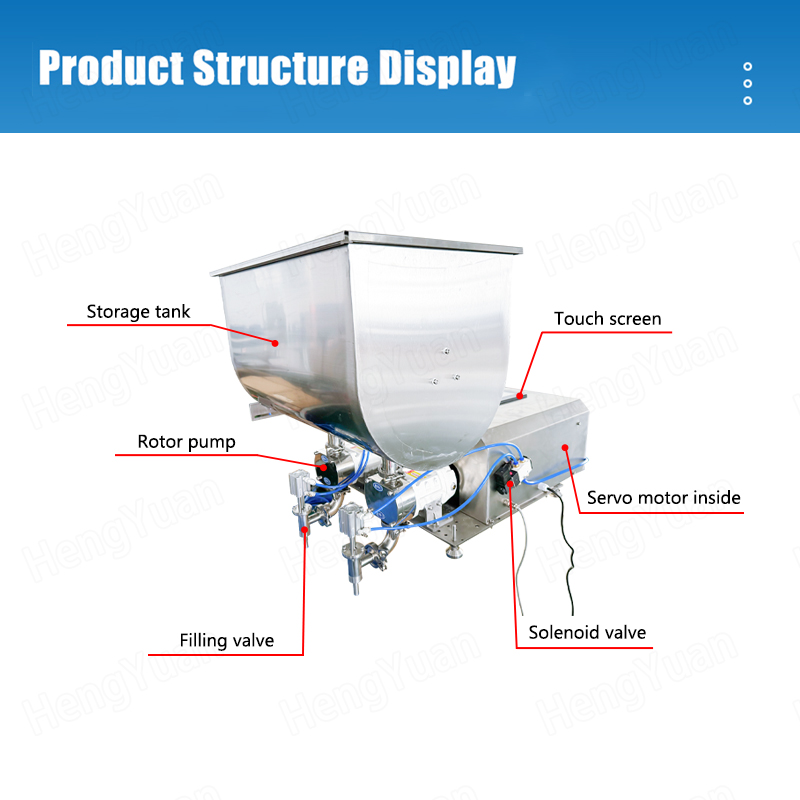

HYRO-S20 Semi-automatic Desktop Rotor Pump Dosing filling machine

Products Description

Main Features

Products Description

Product Introduction

The rotor pump filling machine has advantage of high accuracy when filling thick liquid or paste like peanut buffer, honey, jam, noodle pulp, meat stuffing, tomato paste etc. It is matched with servo motor and PLC to control filling. It is widely used in food, cosmetics, daily chemical industries.

Product Application

Food:

Hot pot seasoning, honey, jelly, jam, yogurt, cream, ice cream, eight treasure porridge, tomato paste, sesame paste, flour paste, maltose, meat stuffing, mustard paste, mashed potatoes, bean paste, salad dressing, chocolate, yeast, butter, animal fat, cheese.

Daily chemical products:

Shampoo, shampoo, shower gel, bath salts, bath milk, soap, hand cream, hand washing liquid, perfume, sunscreen, water, nail polish, emulsion, essence oil, toothpaste, cleansing cream, essence oil, silica gel, rubbing treasure, detergent, laundry detergent, bleach and so on.

Other categories:

Poultry feed, pet ration, Vaseline, cough syrup, industrial glue, white latex, glucose, gelatin, daphnetin, normal saline, paint, waterproof glue, etc.

1) Large filling range: 5-50000ml customized

2) Fast filling speed: servo motor drive, quick response, single second filling 500ml, minimum interval time 0.2 seconds

3) Wide range of application: unique pump head structure, can transport high viscosity materials containing frequent particles( As long as the flow can be filled).

4) No leakage, no pollution: optional Teflon and mechanical seal, work without leakage, flow parts 304 stainless steel material, food hygiene.

5) Easy to wash: pour clean water into the equipment and wash it with high-speed circulating water, which is convenient and sanitary.

Machine Display

Machine Display

English

English Chinese

Chinese