BASIC INFO

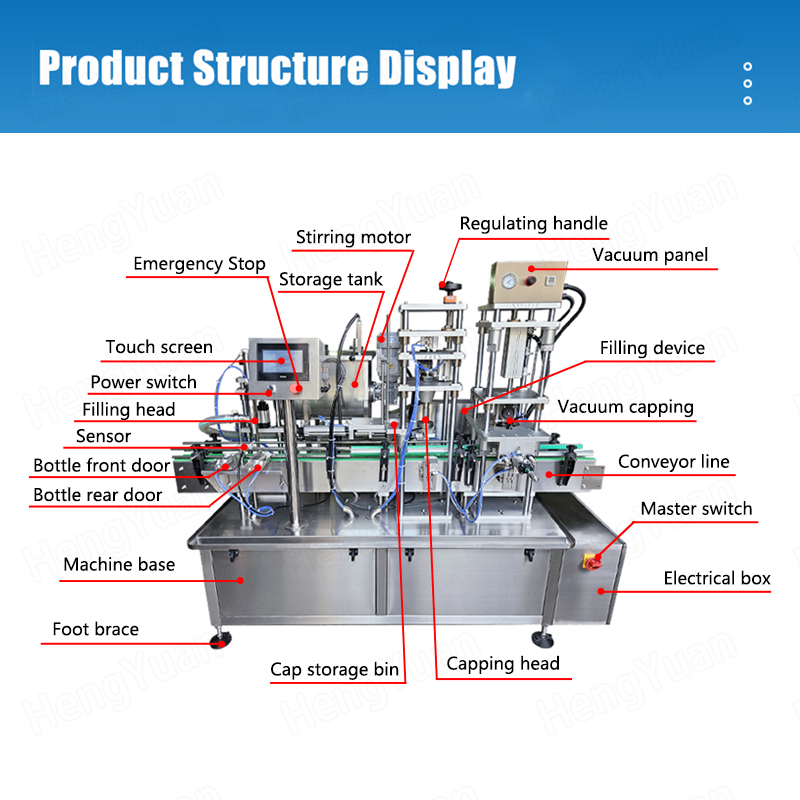

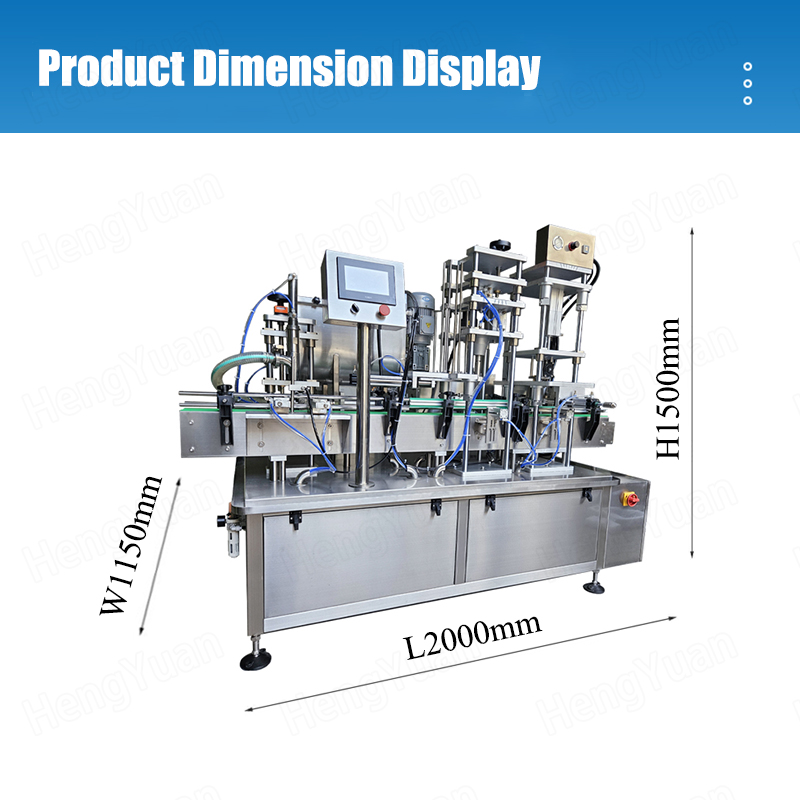

2 in 1 Automatic Glass Jars Filling Vacuum capping machine

Product Description

Product Description

Introduction

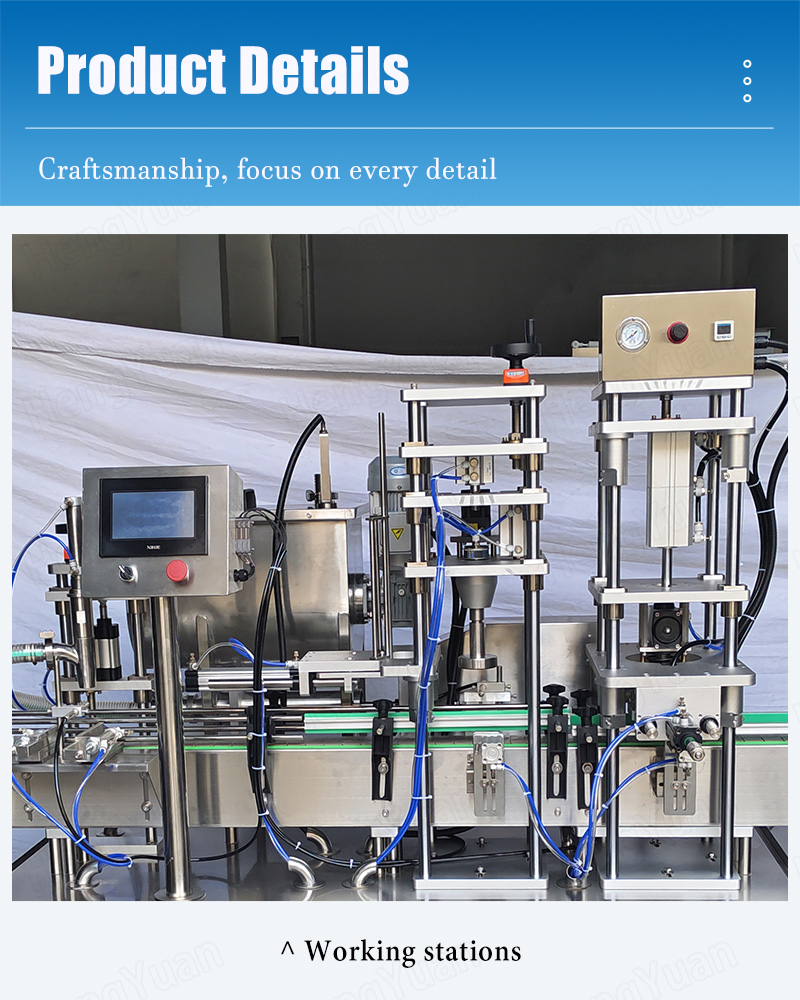

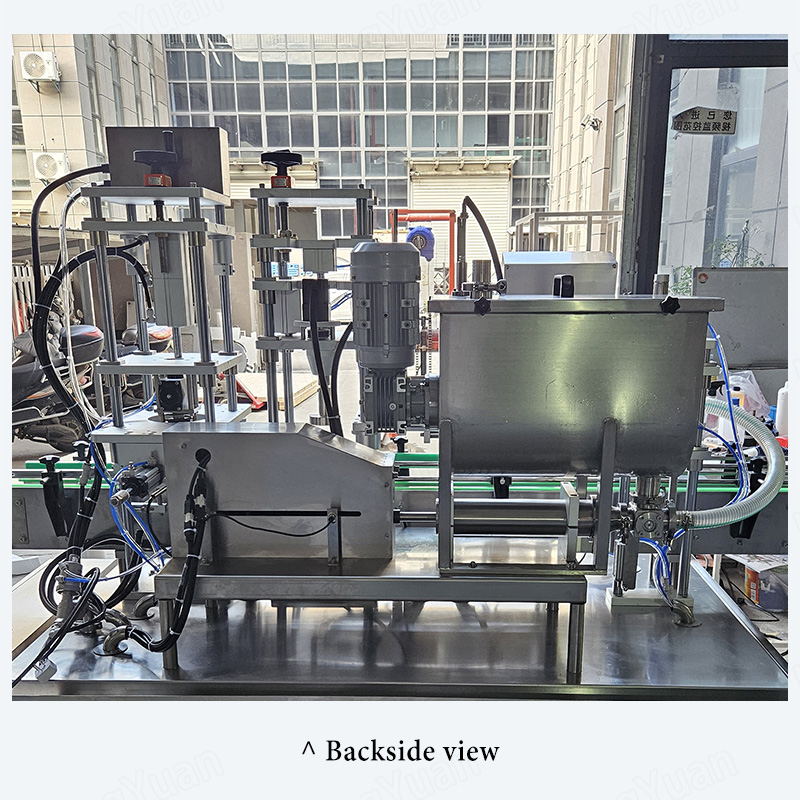

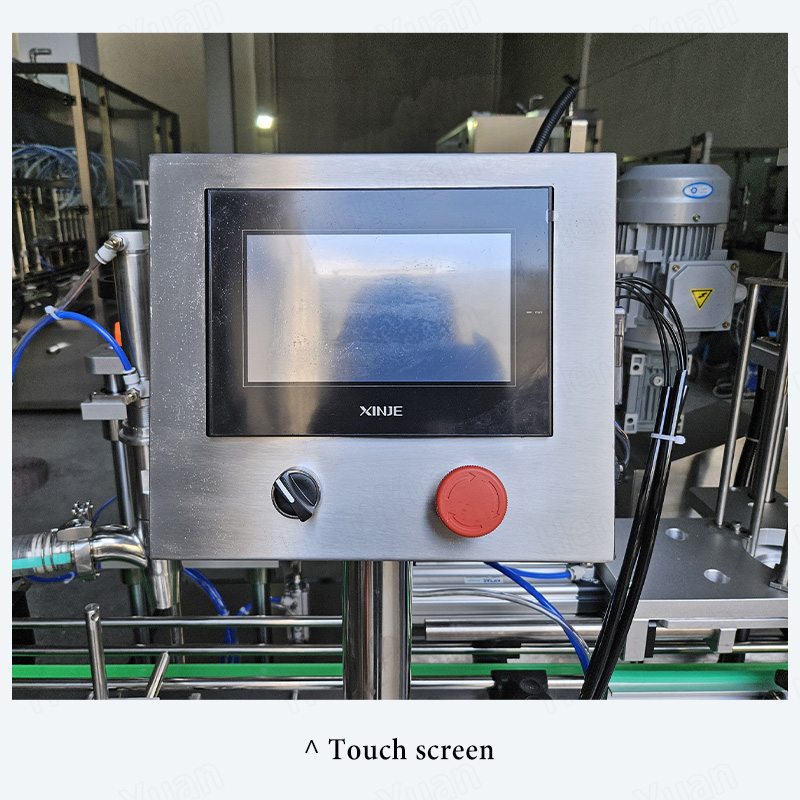

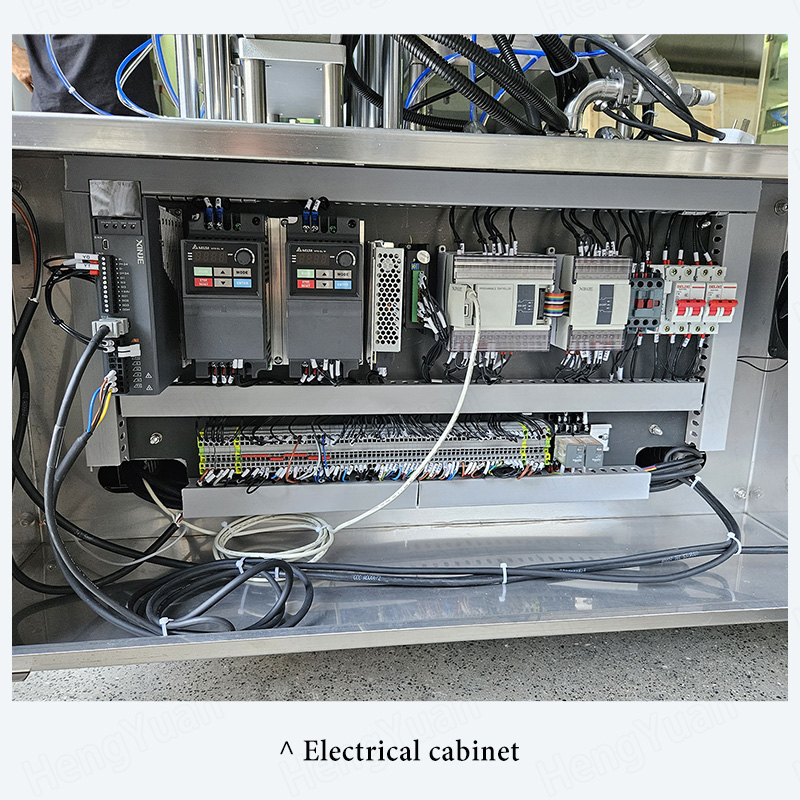

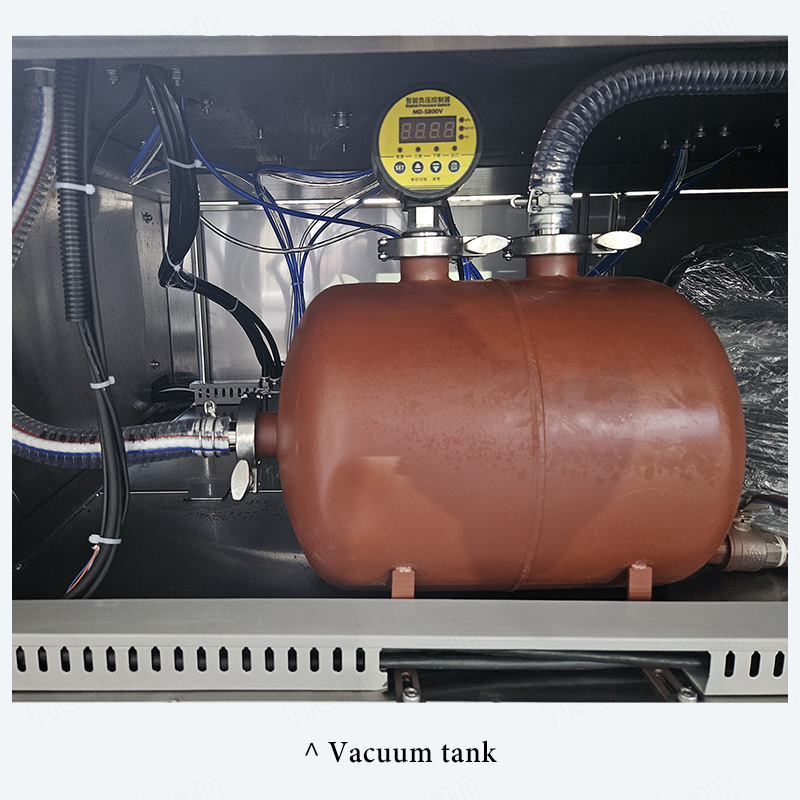

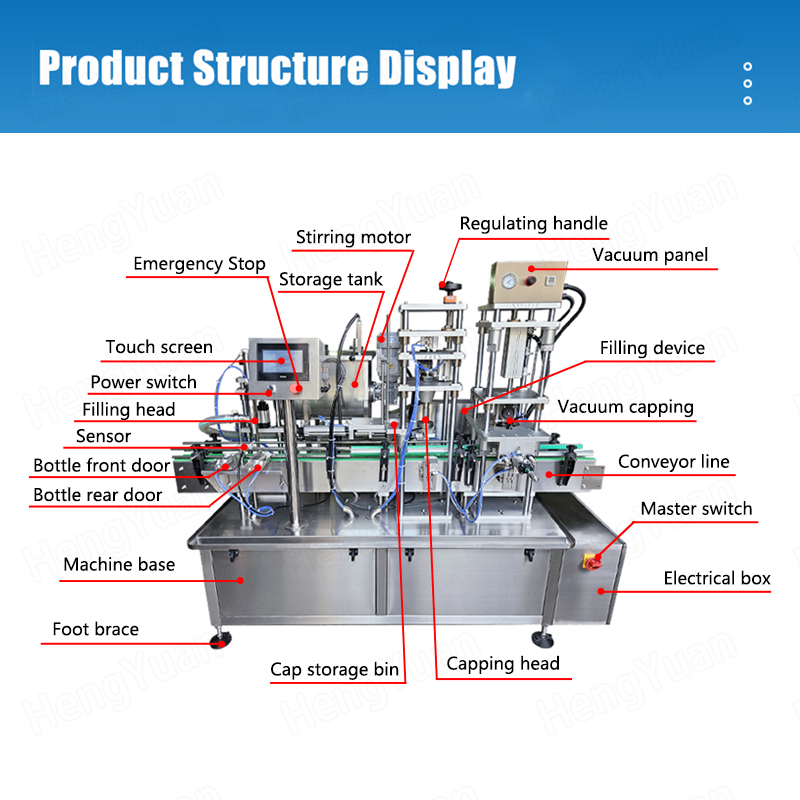

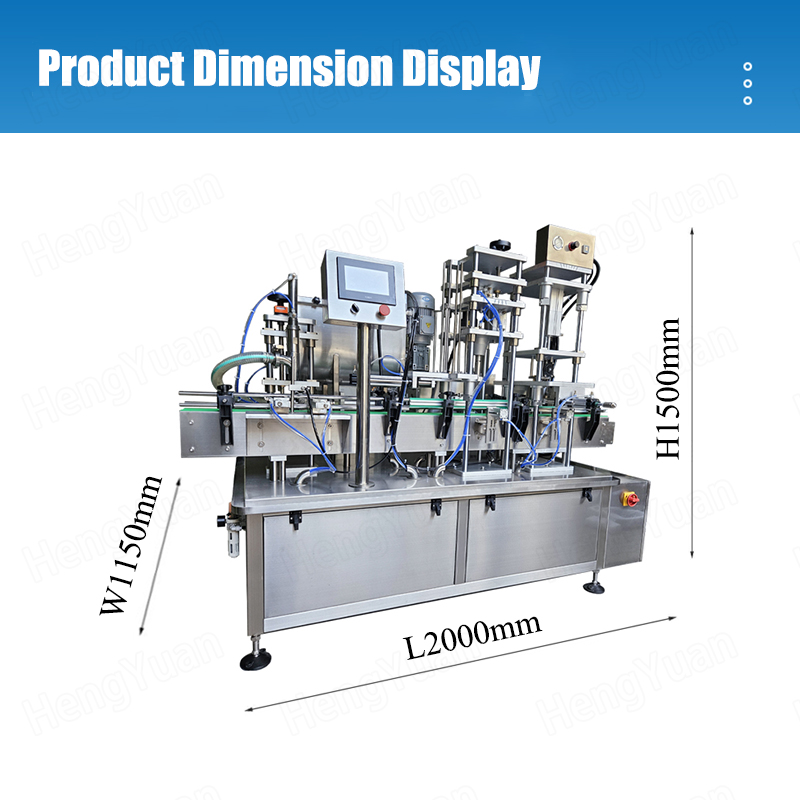

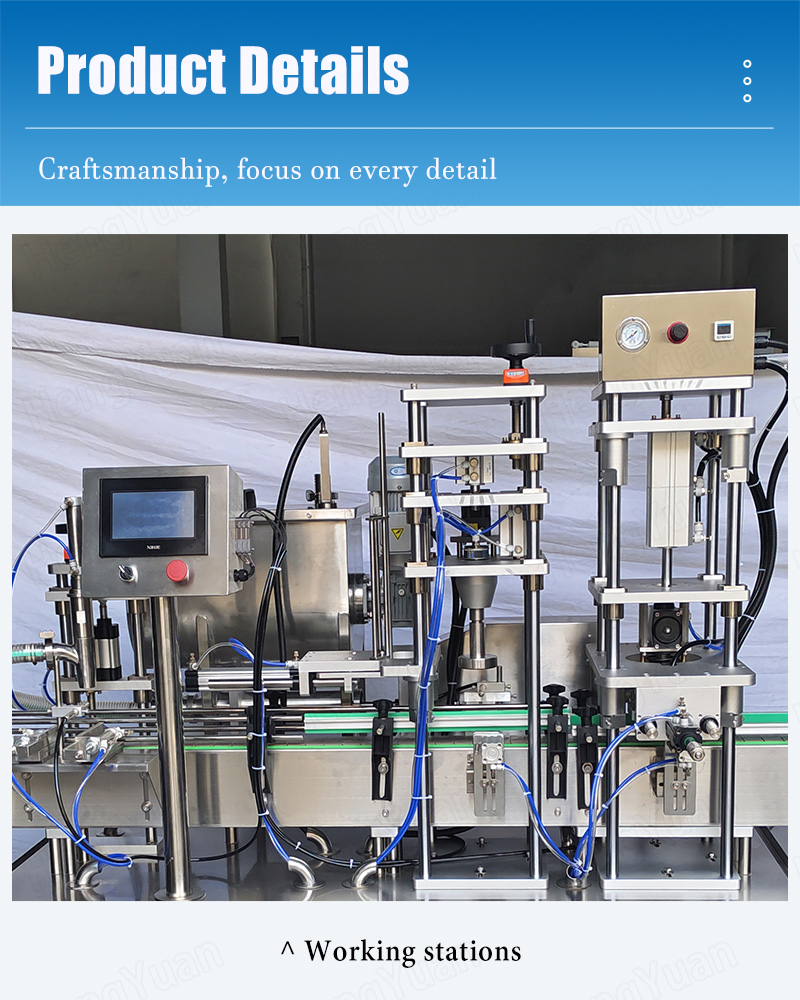

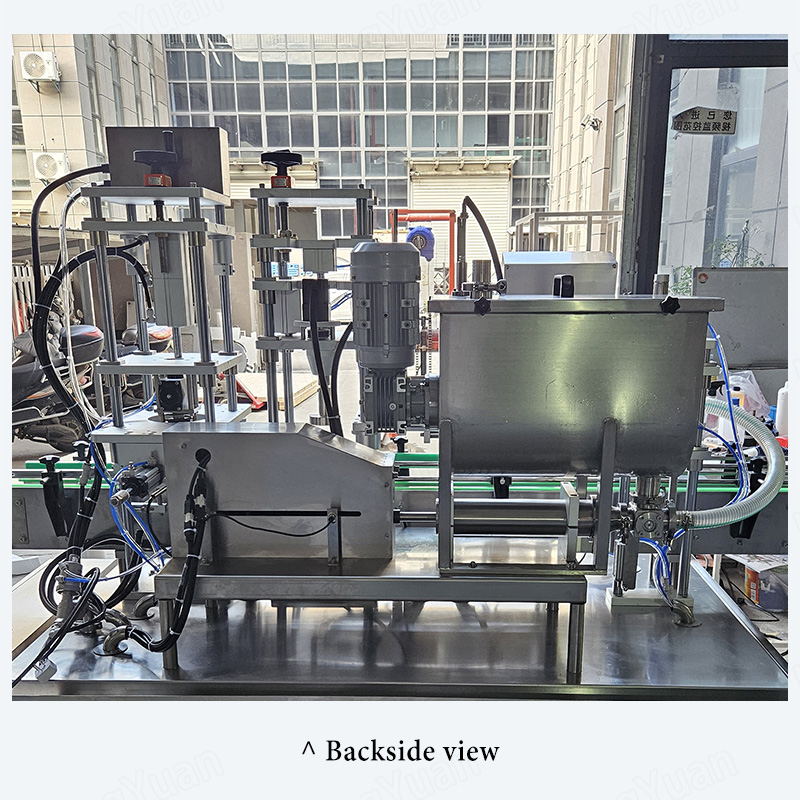

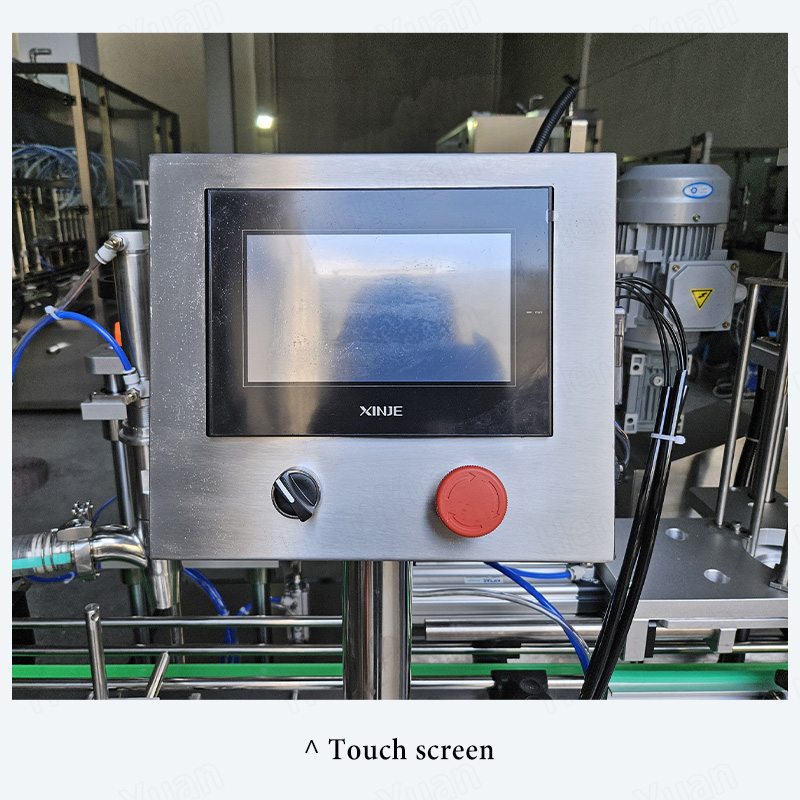

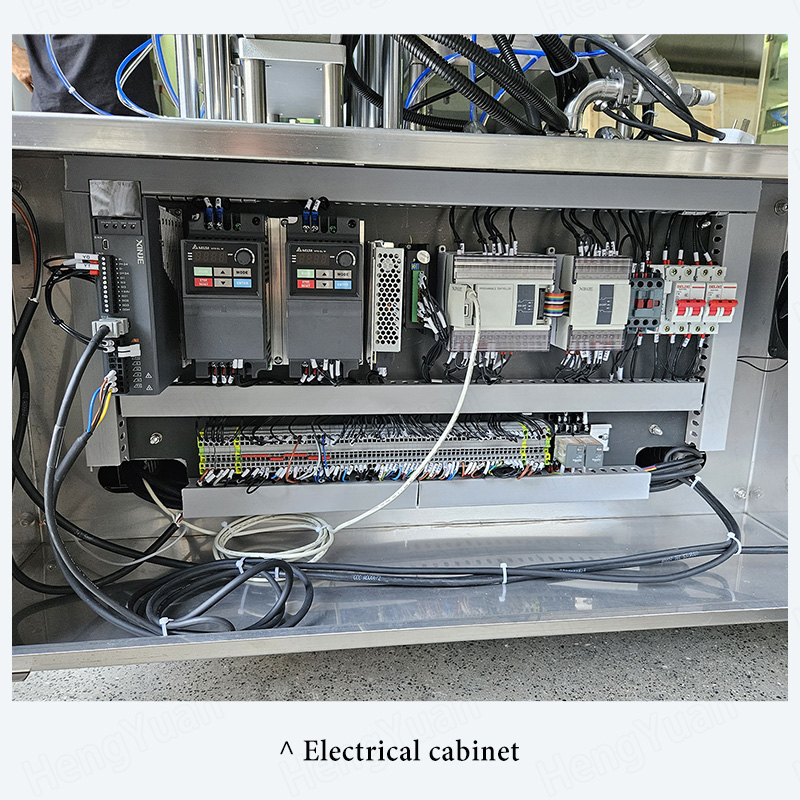

The automatic glass jar sauce filling capping machine adopts servo driving piston type metering and integrates electronic mechanical and pneumatic components. Material hopper has stirring and optional heating function. The electrical and pneumatic components are selected from world-renowned brands, controlled by PLC, with novel design, compact structure and beautiful appearance. It has the characteristics of accurate measurement, stable and reliable performance, high degree of automation, simple operation and convenient maintenance. It is widely used in filling of various (including granule) sauces.

Application

Sauce glass jar filling and vacuum twist-on metal lid capping machine.

For examples: Chili sauce filling capping machine, Beef paste glass jar filling capping machine, Mushroom sauce glass jar filler vacuum capper, Granules sauce glass jar dispensing and capping equipment, Salad sauce glass bottle filling capping machine, Pepper chili bottle dispensing and capping machine, minced meat dispenser, hotpot base filling equipment, vegetable paste filling machine, meat soap dispenser, etc. Any liquid, half-flowing liquid, viscous cream, with or without granules, sauce dispenser, liquid filler, refill equipment.

2 in 1 Automatic Glass Jars Filling Vacuum capping machine

Main Features

1) Frame: Made of 304 stainless steel .

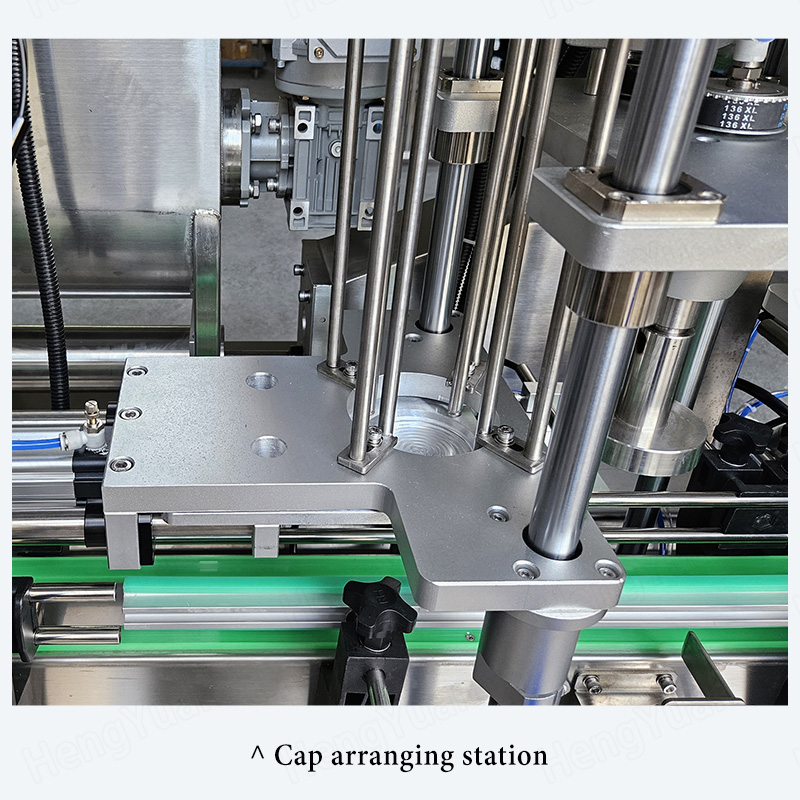

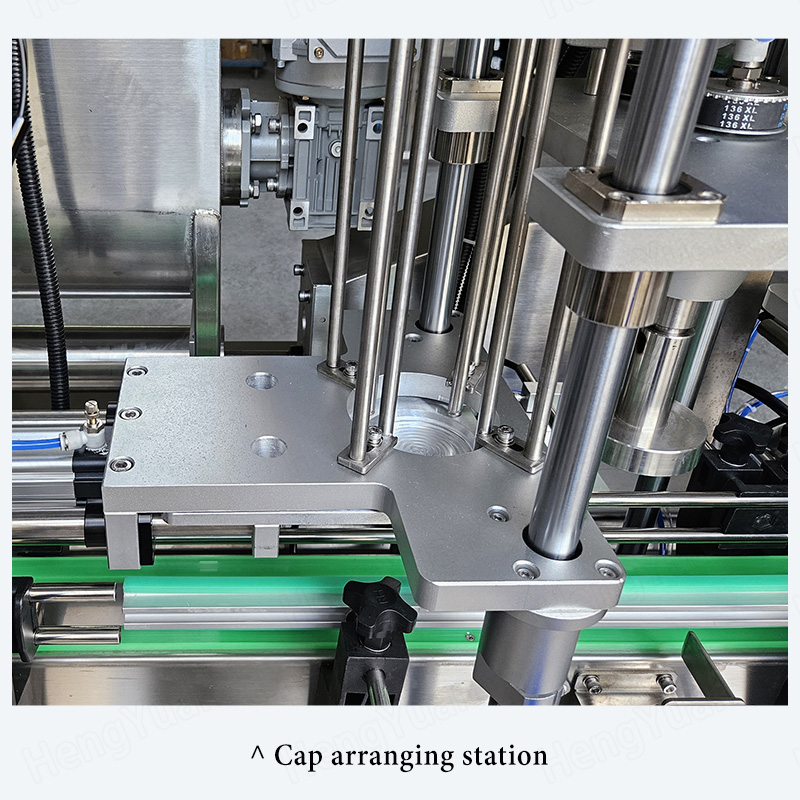

2) Work flow: automatic bottle feeding - automatic filling - automatic cap removal and put cap- automatic vacuuming - automatic cap screwing - automatic bottle output

3) Filling part: The bottom of the material box is designed in an arc shape, which effectively reduces the amount of liquid accumulated in the tail material during automatic filling, and the lowest point of the discharge pipe is designed to drain the remaining material.

4) The material tank can be equipped with an optional stirring function to ensure uniform density of granular materials.

5) The submersible filling method of using a cylinder to drive the filling head can reduce the foaming of materials that are prone to foaming during filling and reduce bottleneck contamination caused by material overflow.

6) Signal detection of bottles ensures that filling will not occur when there is no bottle under the filling head; capping will not occur when there is no bottle under the capping head.

7) When the bottle type is changed, it is simple and quick to replace the corresponding mold.

English

English Chinese

Chinese